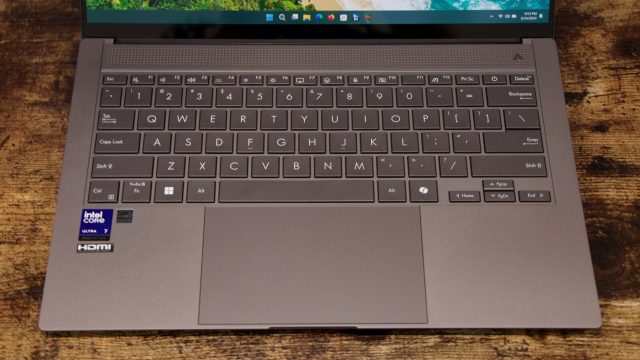

An Asus Zenbook UX5406S with a Lunar Lake-based Core Ultra 7 258V inside.

Andrew Cunningham

An Asus Zenbook UX5406S with a Lunar Lake-based Core Ultra 7 258V inside.

Andrew Cunningham

These high-end Zenbooks usually offer pretty good keyboards and trackpads, and the ones here are comfortable and reliable.

Andrew Cunningham

An HDMI port, a pair of Thunderbolt ports, and a headphone jack.

Andrew Cunningham

Andrew Cunningham

A single USB-A port on the other side of the laptop. Dongles are fine, but we still appreciate when thin-and-light laptops can fit one of these in.

Andrew Cunningham

An HDMI port, a pair of Thunderbolt ports, and a headphone jack.

Andrew Cunningham

A single USB-A port on the other side of the laptop. Dongles are fine, but we still appreciate when thin-and-light laptops can fit one of these in.

Andrew Cunningham

Two things can be true for Intel’s new Core Ultra 200-series processors, codenamed Lunar Lake: They can be both impressive and embarrassing.

Impressive because they perform reasonably well, despite some regressions and inconsistencies, and because they give Intel’s battery life a much-needed boost as the company competes with new Snapdragon X Elite processors from Qualcomm and Ryzen AI chips from AMD. It will also be Intel’s first chip to meet Microsoft’s performance requirements for the Copilot+ features in Windows 11.

Embarrassing because, to get here, Intel had to use another company’s manufacturing facilities to produce a competitive chip.

Intel claims that this is a temporary arrangement, just a bump in the road as the company prepares to scale up its upcoming 18A manufacturing process so it can bring its own chip production back in-house. And maybe that’s true! But years of manufacturing misfires (and early reports of troubles with 18A) have made me reflexively skeptical of any timelines the company gives for its manufacturing operations. And Intel has outsourced some of its manufacturing at the same time it is desperately trying to get other chip designers to manufacture their products in Intel’s factories.

This is a review of Intel’s newest mobile silicon by way of an Asus Zenbook UX5406S with a Core Ultra 7 258V provided by Intel, not a chronicle of Intel’s manufacturing decline and ongoing financial woes. I will mostly focus on telling you whether the chip performs well and whether you should buy it. But it’s a rare situation, where whether it’s a solid chip is not a slam-dunk win for Intel, which might factor into our overall analysis.

About Lunar Lake

A high-level breakdown of Intel’s next-gen Lunar Lake chips, which preserve some of Meteor Lake’s changes while reverting others.

Credit:

Intel

Let’s talk about the composition of Lunar Lake, in brief.

Like last year’s Meteor Lake-based Core Ultra 100 chips, Lunar Lake is a collection of chiplets stitched together via Intel’s Foveros technology. In Meteor Lake, Intel used this to combine several silicon dies manufactured by different companies—Intel made the compute tile where the main CPU cores were housed, while TSMC made the tiles for graphics, I/O, and other functions.